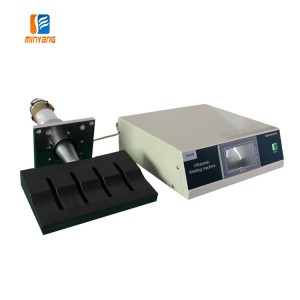

Intelligent Ultrasonic Generator

Specification

| Model | MY-UG04-1520-S |

| Frequency | 15-40khz |

| Power | 800-8000w |

| Voltage | 110V/220v |

| Weight | 18kg |

| Machine Size | 350x380x150mm |

| Warranty | 1 year |

Features

The intelligent ultrasonic generator adopts high performance microprocessor tamper-proof, realizing the electronic control, welding manage all control parameters by microcomputer, frequency control system of intelligent, discharge the inconvenience of manual FM, sonic overload automatic detection, when the real track best resonance point, vibration group keep in low temperature, welding head temperature increase with the frequency of change, The machine is adjusted automatically for more stable operation.

1. High stability: full digital integrated circuit, using high-performance anti-interference processor imported from the United States, while reducing the number of components, simplify the hardware structure, while increasing the voltage regulator function to improve the reliability and stability of the system.

2.Automatic frequency tracking: digital frequency synthesis technology with digital phase locked loop frequency tracking of composite control technology, can eliminate temperature, static load, the processing area, tool wear factors such as the drift of conventional analog regulator to overcome the shortcomings, is advantageous to the parameter adjustment, facilitate with the modification program software, convenient to adjust the control plan and implement a variety of new control strategies.

3.Strong output: the use of IGBT power module and other excitation shock circuit structure, so that the output power is more than 1.5 times the traditional self-excitation circuit.

4. Amplitude 10-100% adjustment: amplitude can be increased or decreased instantaneously in the adjustment process, and can also be fine-tuned to effectively prevent the perfect welding of large and small plastic parts, and effectively reduce shock wear and scalding.

5. Intelligent protection and fault alarm prompt: mold current is too high protection, frequency offset protection, the total output is too large protection. The generator will stop working immediately if the equipment is in trouble, and make corresponding

fault cause prompt until the technical personnel remove the fault.

6.Intelligent closed loop amplitude control technology to achieve amplitude adjustment, not affected by the input voltage and load fluctuations to maintain a constant amplitude output.

7.Energy mode: In the process of ultrasonic welding, the welding effect may be poor because of the unstable air pressure. If the time mode is used, this problem can be effectively avoided and the yield of good product can be improved.

Factory Show

Certification

FAQ

A: Yes, we can. The mould could be customized based on your samples, the voltage can be 110V or 220V, the plug can be replaced with yours before shipment.

A: Please provide the material, size of your product and your welding requirements, such as waterproof, tight air, etc. You'd better provide product 3D drawings , and we can help to check if the drawings need to be changed. So that the plastic product design could meet the requirements of ultrasonic welding technology.