News

-

The introduction of heat staking machine

The principle of the heat staking machine The machine adopts electric heating method to transfer heat from the heating plate to the welding surface of the upper and lower plastic parts. Make its surface melt, and then the heating plate exit quickly, the two pieces of upper and lower parts surface...Read more -

Some factors affecting ultrasonic plastic welding-II

There are many factors affecting ultrasonic plastic welding effect, and we are going to talk about the materials in this article. 1. The ultrasonic welding material differences The welding material difference affects the ultrasonic welding quality, adding fiber and other fillings can improve the ...Read more -

Some factors affecting ultrasonic plastic welding-I

There are many factors affecting ultrasonic plastic welding effect, and here are some of them. 1. Amplitude in the ultrasonic welding process The mechanical amplitude output by acoustic system is a very important parameter in ultrasonic plastics welding. From the perspective of plastic sound pat...Read more -

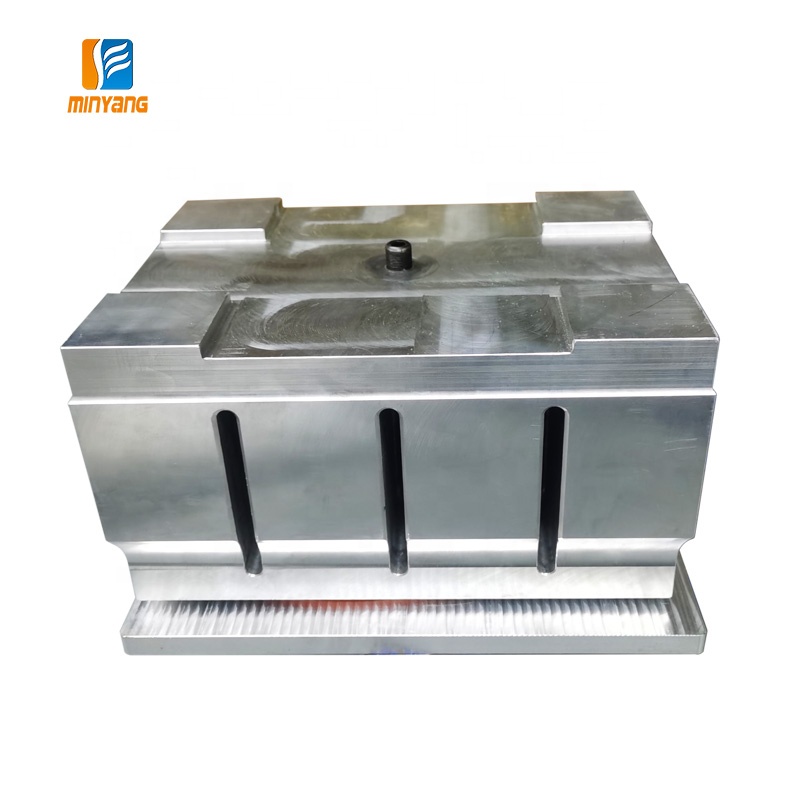

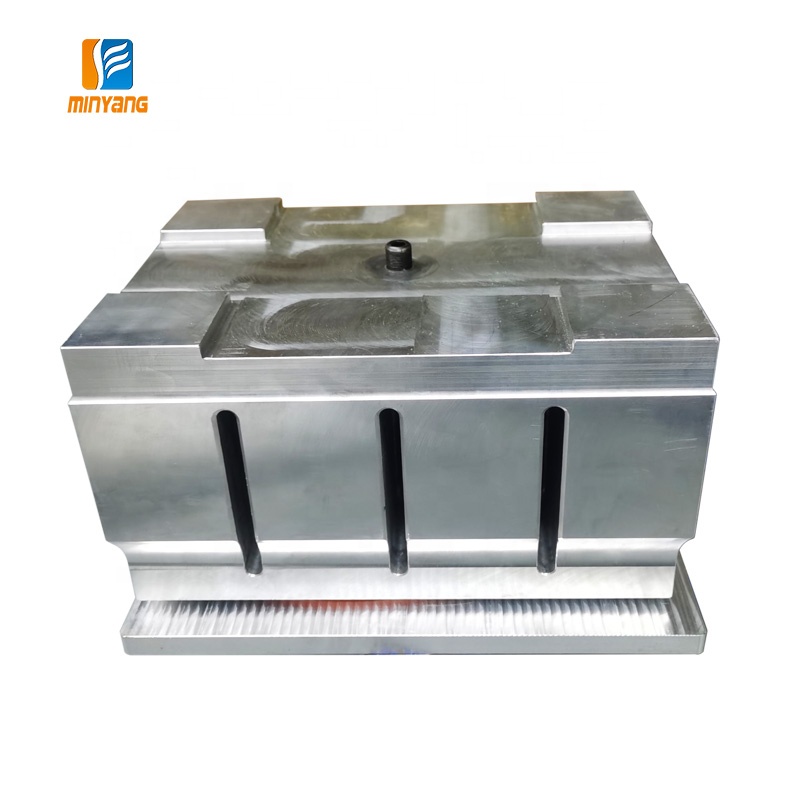

How to make a large size ultrasonic horn–II

In the last news, a design method of large-size strip ultrasonic plastic welding slotted joint was proposed and verified by experiments. Firstly, the strip welding horn is reasonably divided into several units so that the design of slotted welding horn with complex structure is transformed into t...Read more -

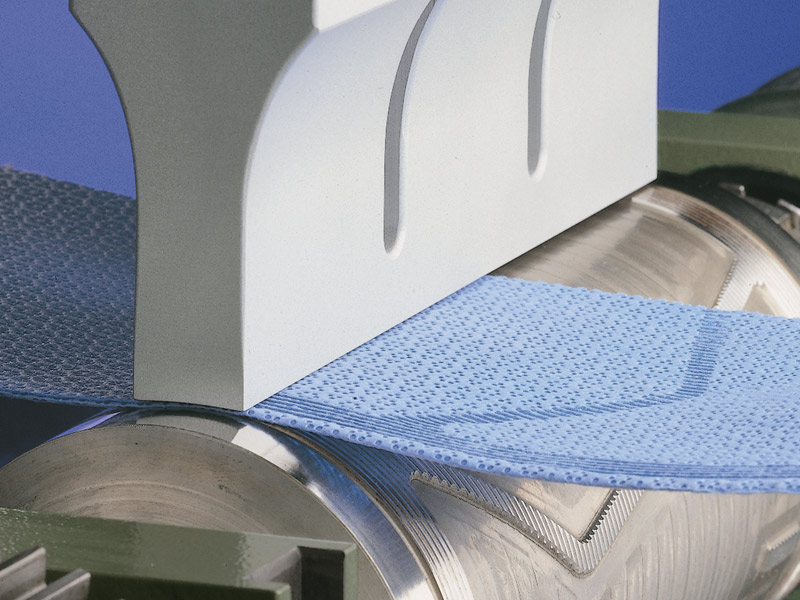

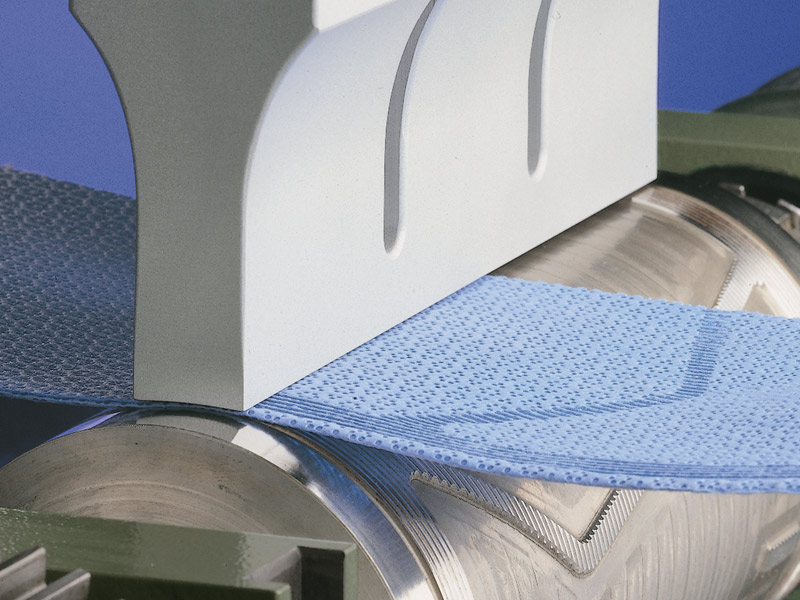

How to make a large size ultrasonic horn–I

Different welding horns are required for different welding objects, no matter near field welding or transmission welding, only half wave length ultrasonic horns can achieve the maximum amplitude of the welding end face. Ultrasonic horns , available with and without amplitude. Ultrasonic plastic w...Read more -

The research of ultrasonic plastic welding equipment structure-II

2. 1 35 kHz Ultrasonic plastic welding equipment structure research requirements For 35 kHz ultrasonic plastic welding mechanical structure, in order to ensure that its structure reasonable development, the following 5 requirements should be met. (1) we should ensure that the energy in the ultra...Read more -

The research of ultrasonic plastic welding equipment structure-I

In the production process of plastic products, ultrasonic welding technology can seal plastic products quickly and efficiently. Besides, in the process of sealing, it is no need to have externally heating plastic products or no need any flux, the welding effect is very good and welding str...Read more -

Double-head high frequency welding machine

What is high frequency ? High frequency wave refers to the electromagnetic wave with frequency greater than 100Khz. The commonly used high frequency is 27.12MHZ, but there is also a larger frequency 40.68MKZ, We need to choose different frequencies according to product characteristics. The prin...Read more -

The design of ultrasonic mould amplitude

Ultrasonic mold is one of the most profound aspects of ultrasonic technology. Even with several years of design and development experience, we firmly believe that only through rigorous testing and quality control can produce the best welding head. Our engineers will weld the acoustic characterist...Read more -

Common Problems in Ultrasonic Welding Process

During use the ultrasonic welding machine, sometimes we will meet some problems, today we will sum them up and let everyone know that to avoid us meet such problems later.in the later operation. 1. In the use of ultrasonic plastic welding , many people choose to use soft or toughness of plastic p...Read more -

The General Ultrasonic Welding Methods

The general ultrasonic welding methods including welding method, riveting welding method, implanting, forming, spot welding, cutting and sealing and so on. 1. Welding method: The welding head vibrating with ultrasonic ultra-high frequency under moderate pressure makes the joint surface of the two...Read more -

Ultrasonic Welding Advantages

When you need to join two molded plastic parts, it’s highly possible ultrasonic welding is the best choice for your application. Ultrasonic welding is an efficient means of fusing thermoplastic parts using the energy from high-frequency, low-amplitude acoustic vibrations. Unlike friction or vibra...Read more